Transforming Industrial Operations with Site-Specific Training

Industrial facilities are the powerhouses of our economy. From factories churning out consumer goods to energy plants powering our cities, these are complex, dynamic environments where safety, proficiency, and innovation are vital.

Alongside complexity, distinctive challenges arise. Providing efficient and effective guidance to new personnel becomes difficult (particularly when crucial institutional knowledge resides solely in the mind of the senior plant manager). Industrial facilities aim to perform in a streamlined fashion, but there is nuance and subtlety when operating technical equipment.

With so much sophistication to capture – not to mention the size of a facility’s footprint – three-ring binders and outdated training videos are inadequate. What if there was a way to leverage technology for more visibility, better insight, enhanced safety, and superior operations?

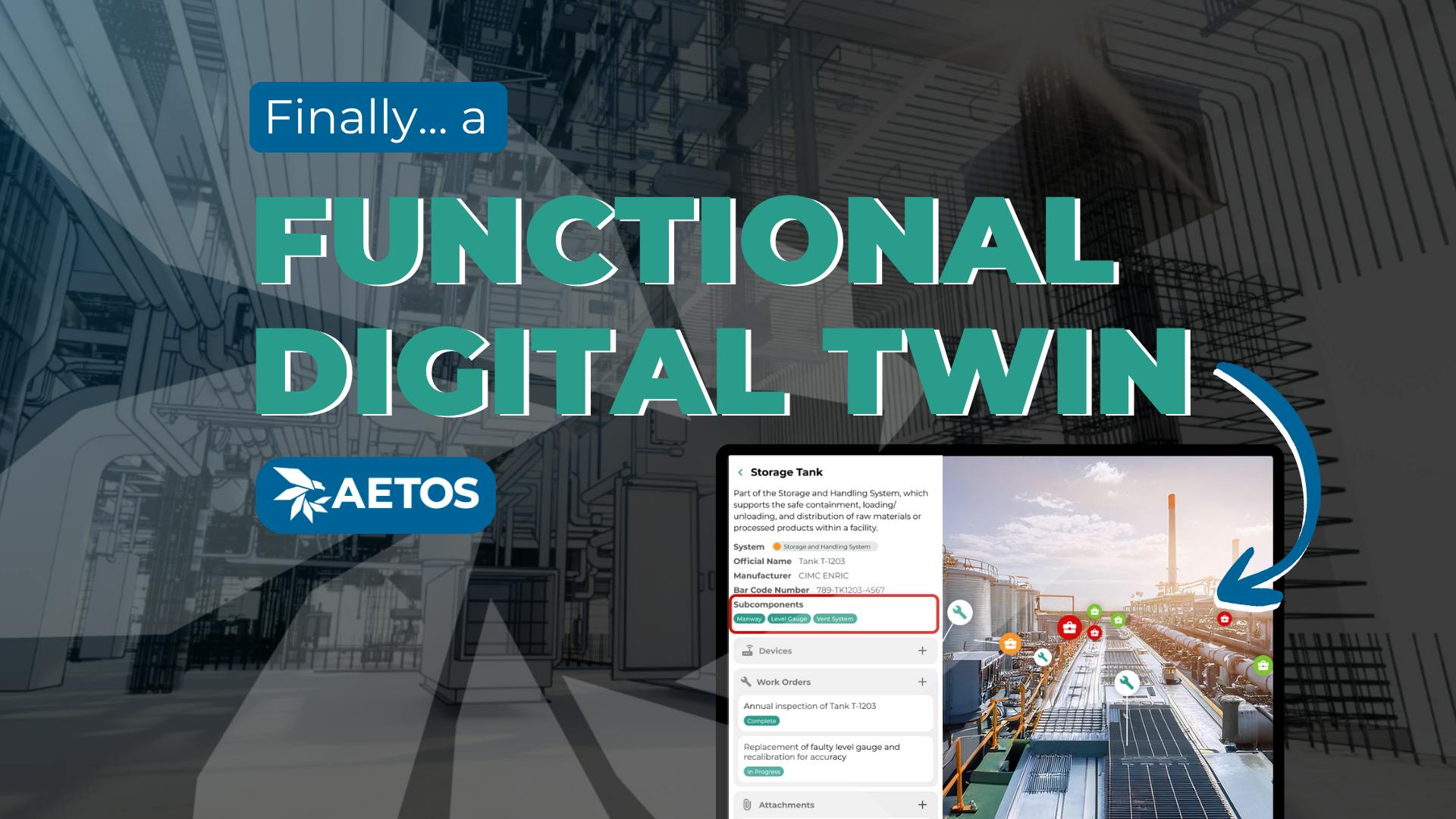

Aetos Imaging's Site-Specific Training is stepping into the breach, offering a transformative, 3D visualization solution for industrial facilities.

“Safety First”

One of the most significant aspects of Aetos Imaging's Site-Specific Training lies in its contribution to workplace safety. The saying "Safety First" holds particularly true in industrial settings where equipment is complex and potential risks are high.

The ability to train and prepare in a risk-free, virtual environment significantly enhances safety measures in several ways. A virtual replica of the facility unlocks great opportunities. New hires and existing staff can leverage the Aetos Operate platform to become familiar with the layout of the facility, the placement of machinery and assets, and the location of safety equipment such as fire extinguishers, emergency exits, and first aid kits.

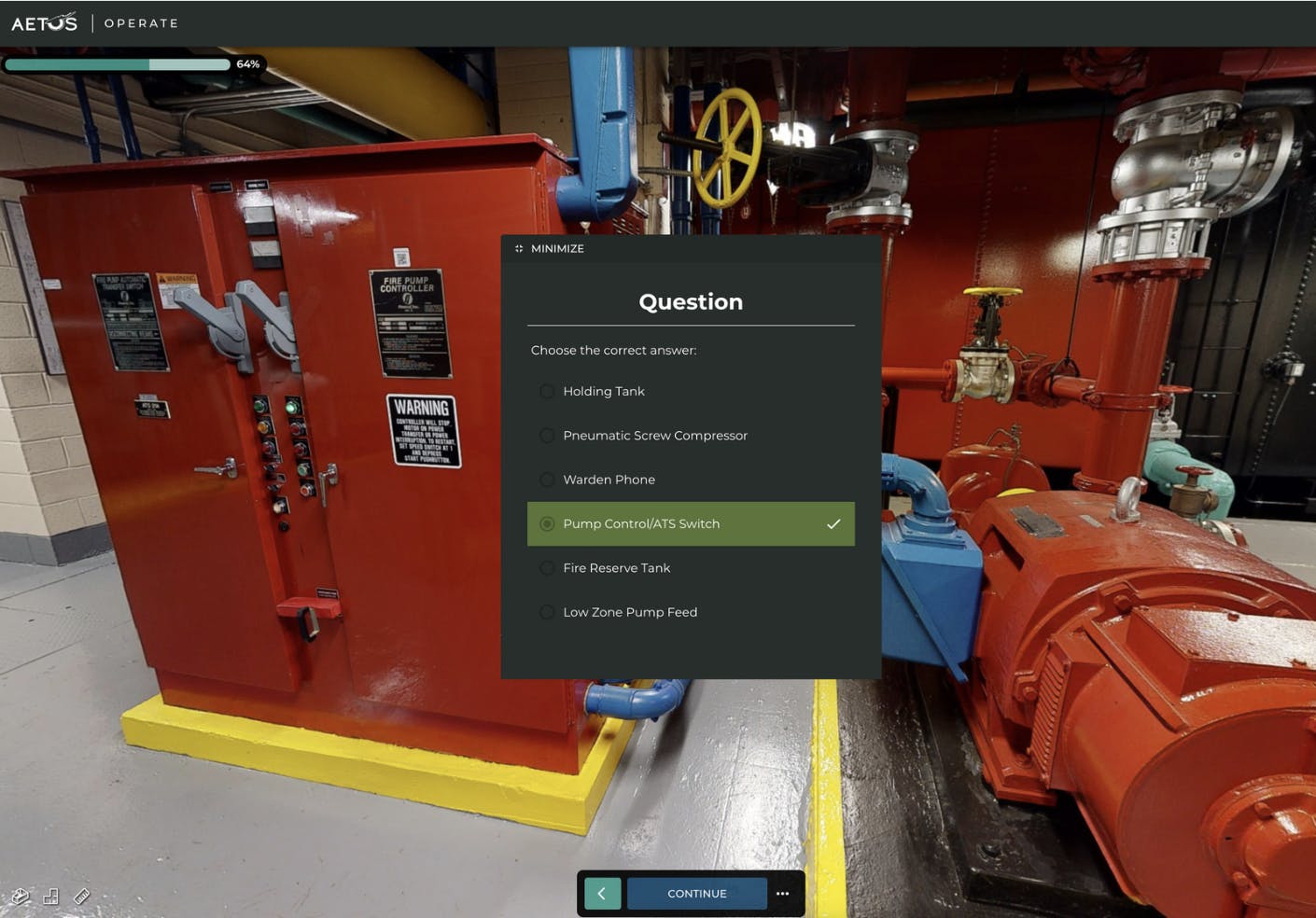

The use of Site-Specific Training also allows for the safe simulation of potentially dangerous scenarios. Workers can practice emergency shutdowns, spill containment, evacuation plans, or hazardous materials handling in the virtual environment – and be assessed on their individual understanding.

Lastly, the ability to conduct safety drills on the Aetos platform means these important exercises can be performed more frequently, without disrupting production schedules or daily operations. This can lead to quicker response times, better resource management, more efficient evacuations, and ultimately, safer work environments.

Assess Personnel Understanding

Beyond immersive learning and realistic simulation, the Site-Specific Training by Aetos Imaging also includes robust features for assessment and reporting.

Each user's interaction with the virtual environment can be tracked and measured. Organizations can use this data to make more informed decisions about their workers, their training modules, and where gaps could be filled to promote better procedures.

Managers can easily access these reports to gain insights into the skills and competencies of their team. Is a new hire showing mastery over a particular machine quickly? Are seasoned veterans consistently adhering to safety procedures during a virtual drill? When answering these kinds of questions, the platform empowers managers to make data-driven decisions about training and workforce development.

These reports are digitally stored for long-term records, useful for both regulatory compliance and internal review. This not only ensures accountability, but it also forms a transparent basis for continual improvement. Aetos combines the power of 3D visualization with analytics, Aetos is setting new standards in training effectiveness and workforce readiness.

Visualize an Entire Facility

Industrial facilities are often sprawling complexes, stretching across acres of land and filled with a dizzying array of machinery, equipment, and infrastructure. The sheer scale and complexity of these environments can make training (and curriculum development) a daunting task.

However, Aetos Imaging's Site-Specific Training presents a powerful solution to this challenge as we capture the entirety of a facility and present it in a digestible, interactive format.

By creating a comprehensive 3D replica of an industrial facility, Aetos makes it possible to virtually traverse the entire complex without leaving your desk. Each section, each machine, each control room can be explored in detail, allowing workers to understand the context and location of their tasks within the larger facility. This ability to visualize and interact with the whole facility makes training more engaging, comprehensive, and effective.

The Site-Specific Training feature on the Aetos platform ensures every nuance of a facility is captured and replicated in an interactive 3D model. This isn't just about a virtual tour of the factory floor – it's about providing workers with 3D visualization support in their specific workspace.

Moreover, this approach can drastically reduce the time it takes to get a new hire up to speed. Traditional onboarding processes take weeks – sometimes months – as new hires are shown around the facility, introduced to various equipment, and walked through their tasks.

Adopt and implement Site-Specific Training and new hires can immerse themselves in their work environment from day one, significantly reducing the learning curve with an enhanced onboarding process.

Beyond training, this 3D model serves as an invaluable reference tool. Any time a worker needs to locate a piece of equipment, understand a process, or even find the nearest emergency exit, they can refer to the model. (Read more about how our Visual Asset Management feature is the comprehensive database you’ve been looking for.)

Minimize Conjecture. Maximize Confidence

Too often, on-site personnel rely on outdated binders and their own memory to perform a task. How often does a technician read a task on a clipboard and think, “I wish this would just show me which lever to turn.” When it comes to industrial settings, there’s no room for speculation and guesswork.

With Aetos, we help organizations minimize conjecture and maximize confidence. Our most successful clients leverage our platform to deliver clarity and technical know-how to their workers – and some even use our platform for assisting their service providers.

The ability to repeatedly interact with Site-Specific Training of the facility also means that personnel can become deeply familiar with their work environment. This familiarity breeds assurance, as employees know exactly where everything is, how everything works, and what to do in different situations.

This repeated and practiced exposure can greatly accelerate onboarding, reduce downtime, and improve overall operational productivity. But the benefits go beyond just training, as Aetos can help with sustainability goals, collaboration opportunities, troubleshooting, innovating, and live network readings to name a few.

Site-Specific Training: A New Dawn for Industrial Operations

In a rapidly evolving industrial landscape where technology, automation, and innovation are transforming operations, Aetos Imaging's Site-Specific Training feature offers an opportunity for companies to leapfrog into the future. It's an intelligent investment that can deliver measurable benefits, from enhanced safety and facility understanding to increased operational proficiency and worker confidence.

With Site-Specific Training, organizations are elevating safety standards, instilling confidence in employees, and contributing to the creation of work environments where safety is deeply ingrained in the everyday operation. Industrial facilities can now provide a powerful, user-friendly tool that enhances understanding, accelerates training, and simplifies daily operations, making them more accessible, comprehensible, and manageable than ever before.