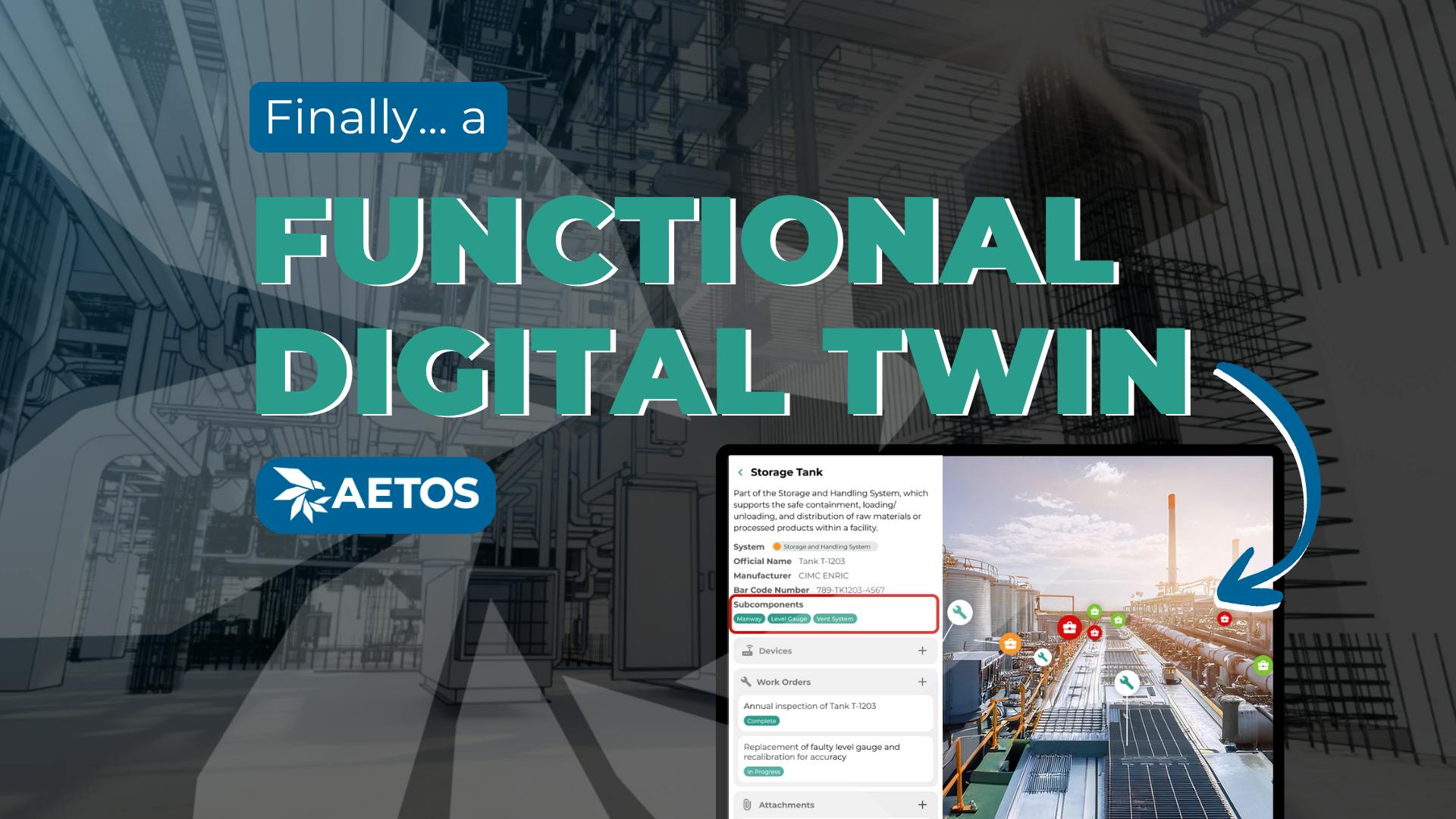

Finally, a Functional Digital Twin.

Before we highlight how you can have a functional digital twin, we're going to park on the idea of digital twins for a minute.

"Digital twin" has become a common phrase in industrial circles, but it means very different things depending on who’s speaking.

For some, it’s a 3D scan you pull up once a month; for others, it’s part of a complex simulation; and for others still, it's just some amorphous idea in some super-futuristic sci-fi book.

Digital twins are positioned as the next tool to add to the proverbial tool belt, but so far have underdelivered on the promise.

There are image capturing solutions in the market that claim to support daily operations, but they lack true operational support.

There are CMMS softwares in the market that claim to be intuitive and helpful for daily tasks. And although they can improve operations, they certainly lack clarity that modern-day workers need.

Each one helps in certain areas, but none of them truly lets frontline technicians see and do their work in the same place.

A truly functional digital twin is the tool many industrial teams have been looking for. In this post, we’ll break down how a functional digital twin combines the best of a 360° scan and a CMMS to deliver value and clarity for day‑to‑day plant operations.

Why image‑capture alone isn’t enough

Using a 360° camera has become an easy way to document a site. Vendors like OpenSpace and Drondeploy have popularized this method by letting users make scan their sites with consumer‑grade cameras. It’s simple and cost‑effective – anyone can walk through a facility and record progress.

A scan, however, is just that: a 3D model that provides some context but no real action. There’s no added functionality, and no way to overlay real‑time data. When teams need to compare the site to a design model or to track maintenance tasks, the limits become clear.

More advanced 3D digital twins, such as those created by Matterport or NavVis, solve some of those issues. They use laser scanners or drone photogrammetry to build detailed spatial models.

These models are valuable for construction and facility planning, but they are also limited in providing specialized functionality and a limited in the support they can give to day‑to‑day operations.

Why CMMS doesn’t give you the full picture

Computerized maintenance management systems (CMMS) emerged to organize work orders, schedule preventive maintenance and store equipment data. This digitization process has improved the operations in many industries.

The best CMMS solutions replaced pen‑and‑paper logs with databases and spreadsheets. Indeed, that change brought efficiency, but the typical CMMS still relies on text and numbers to describe equipment and tasks.

Although this is typical in many organizations, visualization is a trend that is rapidly effecting even the most established CMMS providers.

As a quick example, if you’re a technician on the floor, you might read a work order in a typical CMMS telling you to “check pump #241” or “inspect HVAC unit on roof level.” You then have to translate those words into a mental map of the plant. Without visual context, it’s easy to misread a location or miss an important connection between systems.

(And we have a lot more of those examples we can share at another time.)

Introducing a Functional digital twin

Aetos takes a different approach. We’ve built what we call a Visual Maintenance Management System (VMMS). At its core, it’s a digital twin of your facility, but it’s designed for everyday use. Complex tasks and critical standard operating procedures are now visualized for your technicians and operators across your plants.

That’s what we set out to change: combining 360° image capture with robust CMMS capabilities for the boots-on-the-ground operators and technicians.

We threw together a short list of how Aetos is providing functionality to O&M teams across the country:

- Aetos is Visual and Interactive: A VMMS integrates dynamic, visual information and provides an interactive 3D environment. You aren’t looking at static pictures; you’re moving through a digital version of your plant. You can see equipment with spatial context, view its real‑time (or historical) performance data and access the relevant operating procedure or training module.

- Aetos Provides Operational Context – By giving technicians visual context, a VMMS allows them to see their operational data in real time and to interact with equipment in a virtual setting. Work orders become visual tasks. Instead of reading “replace filter on air unit 3A,” a technician clicks on the unit in the digital twin and follows the visual workflow.

- Aetos is Mobile and Very Accessible – The platform is cloud‑backed and works on mobile devices. A technician can walk the plant floor with a tablet and update tasks as they go. A manager can review progress from the office or from another facility.

- Aetos Unlocks Integrated Learning – Training and knowledge management are built into the platform. New hires can explore the facility virtually, see how tasks are done and practice in a safe environment. [Learn More]

Measurable benefits

We’ve seen measurable results from our customers. By providing immersive training and clear visual context, teams have cut onboarding times by half and eliminated non‑visual work orders.

On average, downtime and operational costs have decreased by 20%, and overall productivity has risen by more than 15%. These improvements come from giving people the context they need to do their jobs efficiently.

Another measurable benefit is remote collaboration and integrated data. With Aetos, teams can confirm asset details, provide digital proof and guide on‑site technicians from anywhere (described as the "Google Street View for industrial operations")

Senior engineers can assist and troubleshoot without stepping foot on‑site, effectively being in two places at once. The platform promotes significantly better asset management, historical maintenance records, standard operating procedures and work orders directly into the 3D digital twin.

Having this information at their fingertips gives technicians unprecedented context before they go on site, which cuts down on unnecessary visits (including those 2 a.m. call‑outs) and speeds up critical tasks.

How this helps plant managers (specifically)

For plant managers, a functional digital twin means less guessing and more clarity. You can:

- Navigate your facility from your desk to plan maintenance or coordinate with remote experts.

- See real‑time data on performance and condition, making it easier to prioritize tasks and prevent failures.

- Provide clearer instructions to teams, reducing errors and repeat visits.

- Capture and share institutional best practices and close the growing knowledge gap.

There's more that we unlock for plant managers - as well as other roles in other industries! Check out our bank of Use Cases and see how we can help your team today.

Ready to take a closer look?

A functional digital twin isn’t a buzzword. Yet it has created a lot of buzz in the industry!

It’s a tool that helps your team see and understand their work. Instead of separating documentation, maintenance schedules and training materials, a VMMS unifies them in one visual platform.

If you’d like to explore how a Visual Maintenance Management System could fit into your plant, register for a free demo.