See Problems.

Before They Happen.

IoT data and intelligent analysis for a more connected management process.

Request an IoT-Specific Demo

Trusted by

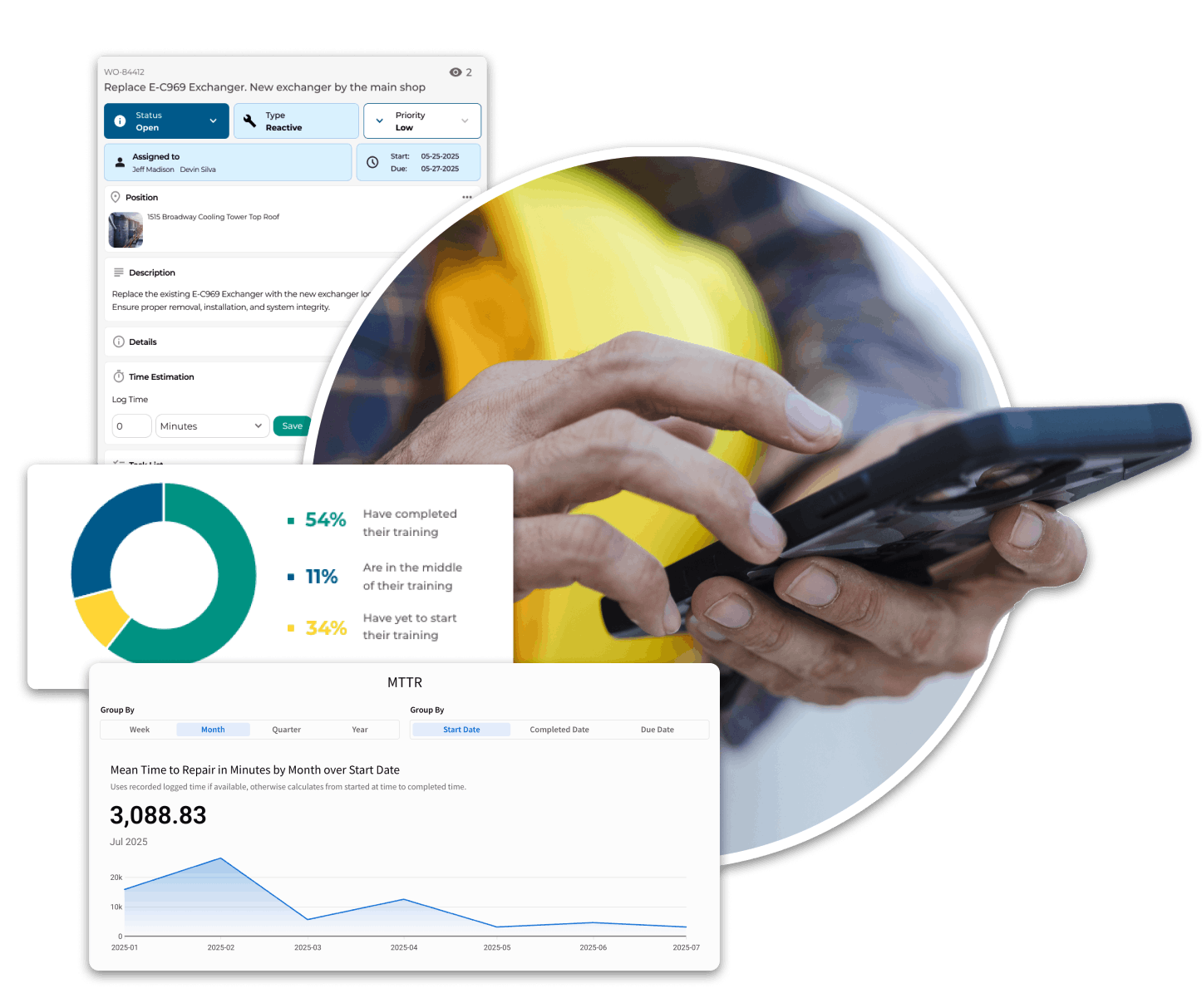

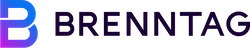

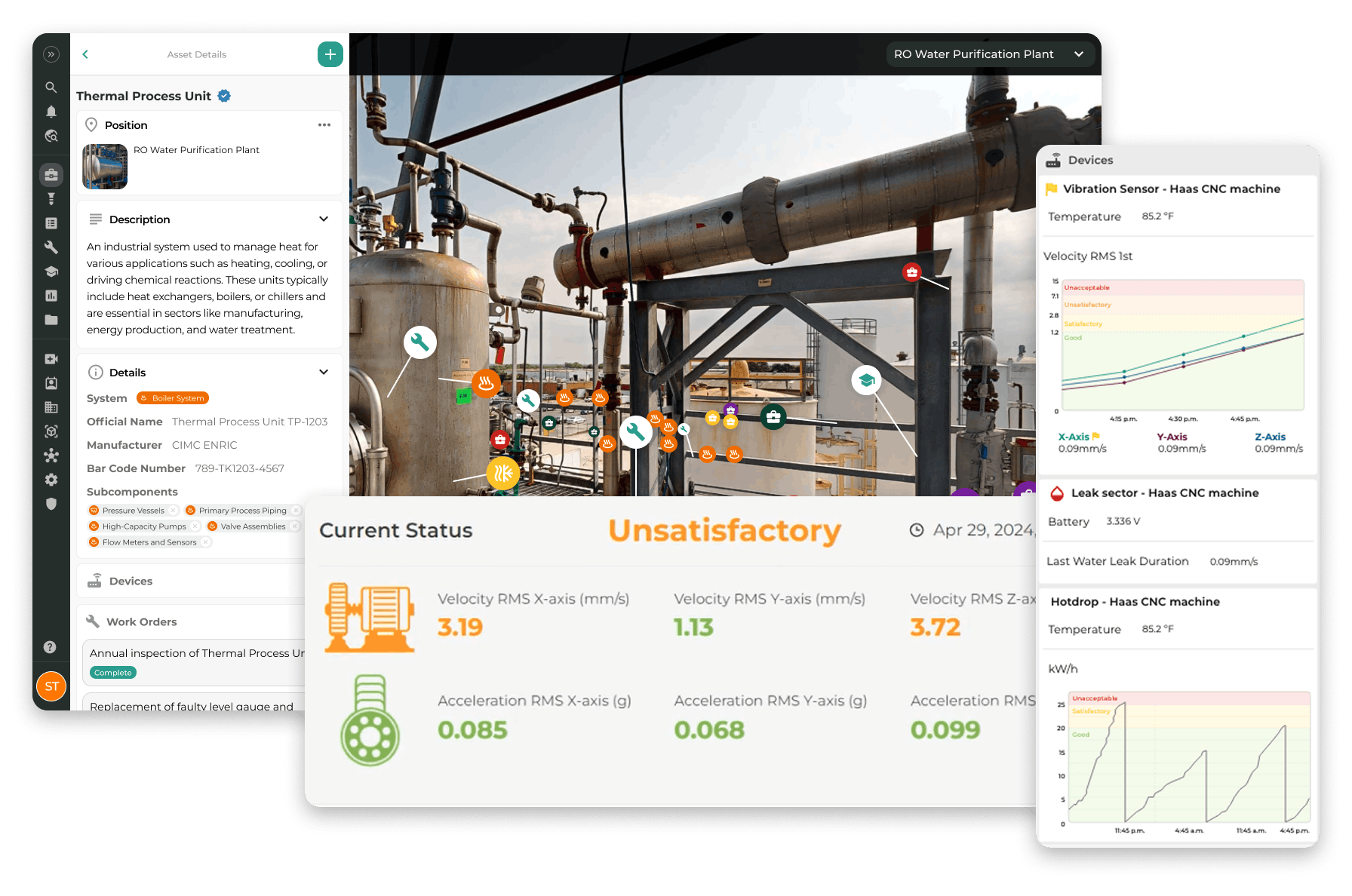

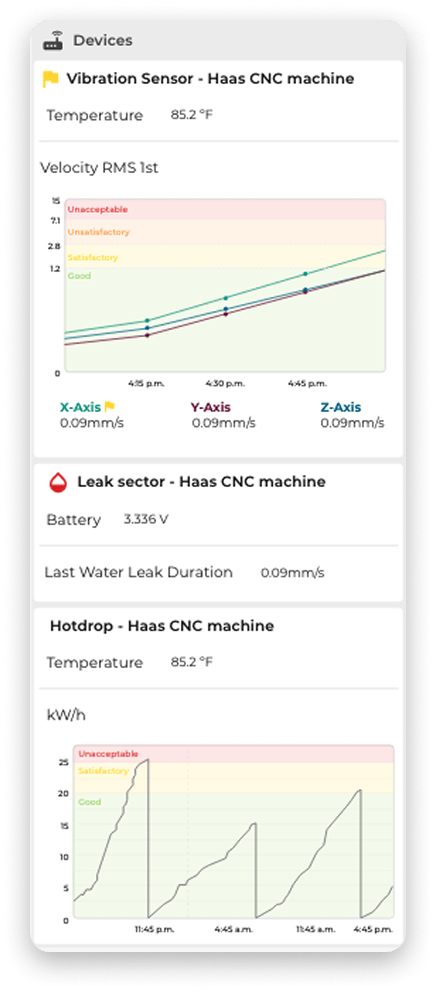

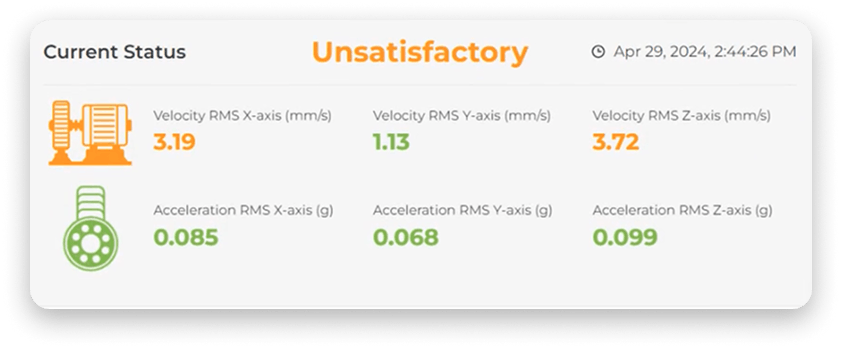

See the Data Your Facility Is Already Producing

Capture equipment performance and monitor various datapoints like vibration, temperature, alignment, and more – from anywhere.

Anticipate Failures Before They Occur

Utilize real-time data from connected sensors to identify patterns and predict equipment malfunctions, allowing for proactive intervention.

Optimize Your Maintenance Schedules

Reactive, calendar-based maintenance is a thing of the past. Use IoT data for condition-based and predictive strategies, saving time and resources while maximizing asset lifespan.

Gain Deeper Insights into Asset Health and Performance

Understand how your equipment is truly operating without having to stand next to it. IoT data provides valuable insights into performance trends, equipment statuses, and asset health.

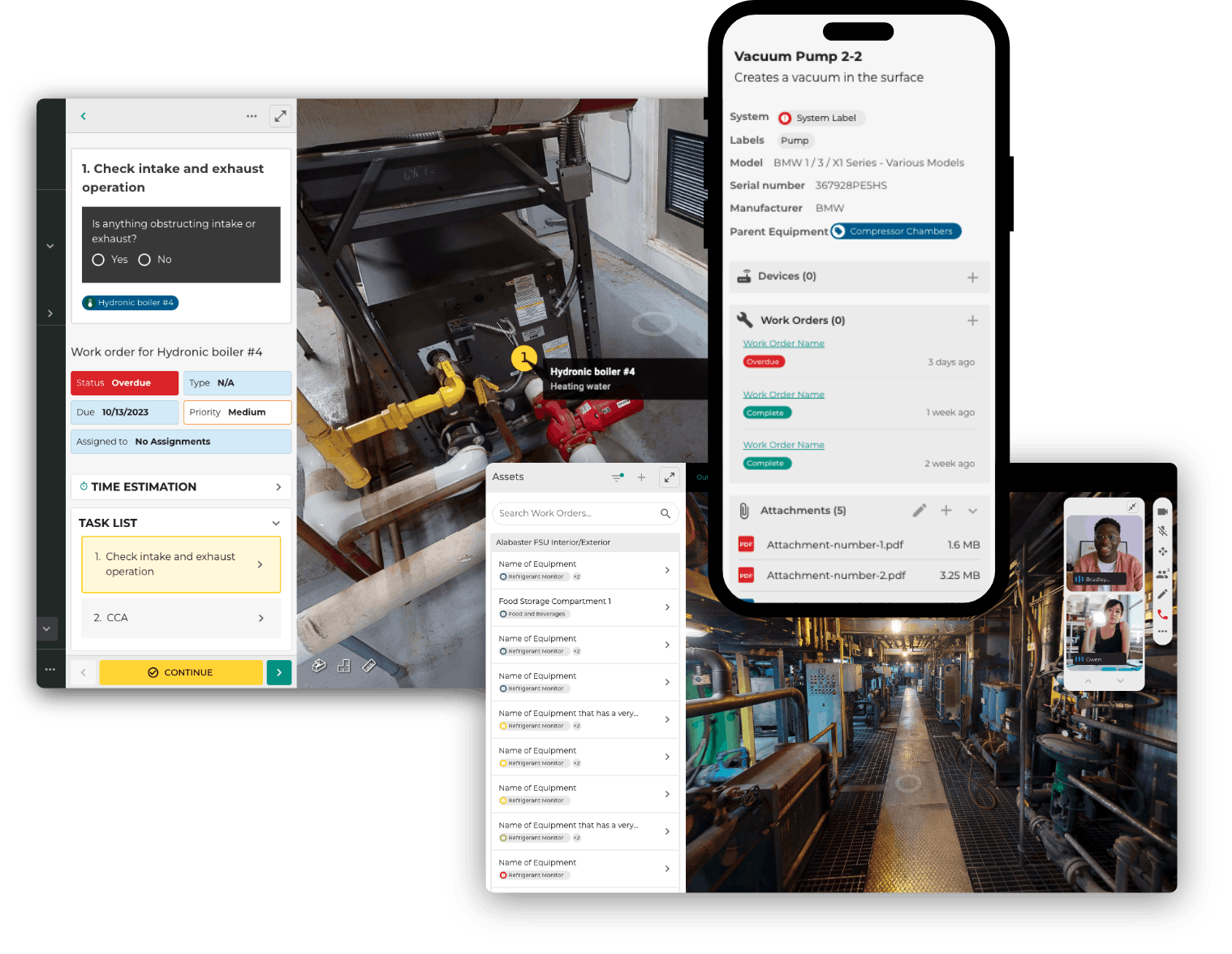

Visual Work Instructions

See how organizations are utilizing immersive digital twin technology for improving their technicians' experience.

Related Content

Operations & Maintenance

Aetos is the most visual solution for any O&M team.

Enterprise Asset Management

Improve maintenance, extend asset lifespan, and boost overall efficiency with our comprehensive EAM solution.

Maintenance Management

Organize tasks, track progress, and ensure your equipment runs smoothly with a visual maintenance management system.