The Connected Worker for the Present and Future: Why Southern Company is Using Aetos

An employee on the production line, a technician in the field, and the operator managing work order schedules all have something in common: their job is built around efficiency.

Time directly impacts P&L.

And lag – whether it be in communication, task completion, decision-making, or in confirming equipment status or accuracy – directly impacts time.

Cutting lag is integral for faster, more efficient operations. The best way to do it? By connecting your workforce to the tools, knowledge, and SOPs.

Some solutions connect information, but do it in a way that still requires interpretation; spreadsheets and itemized lists are static and only so helpful as an employee’s memory allows.

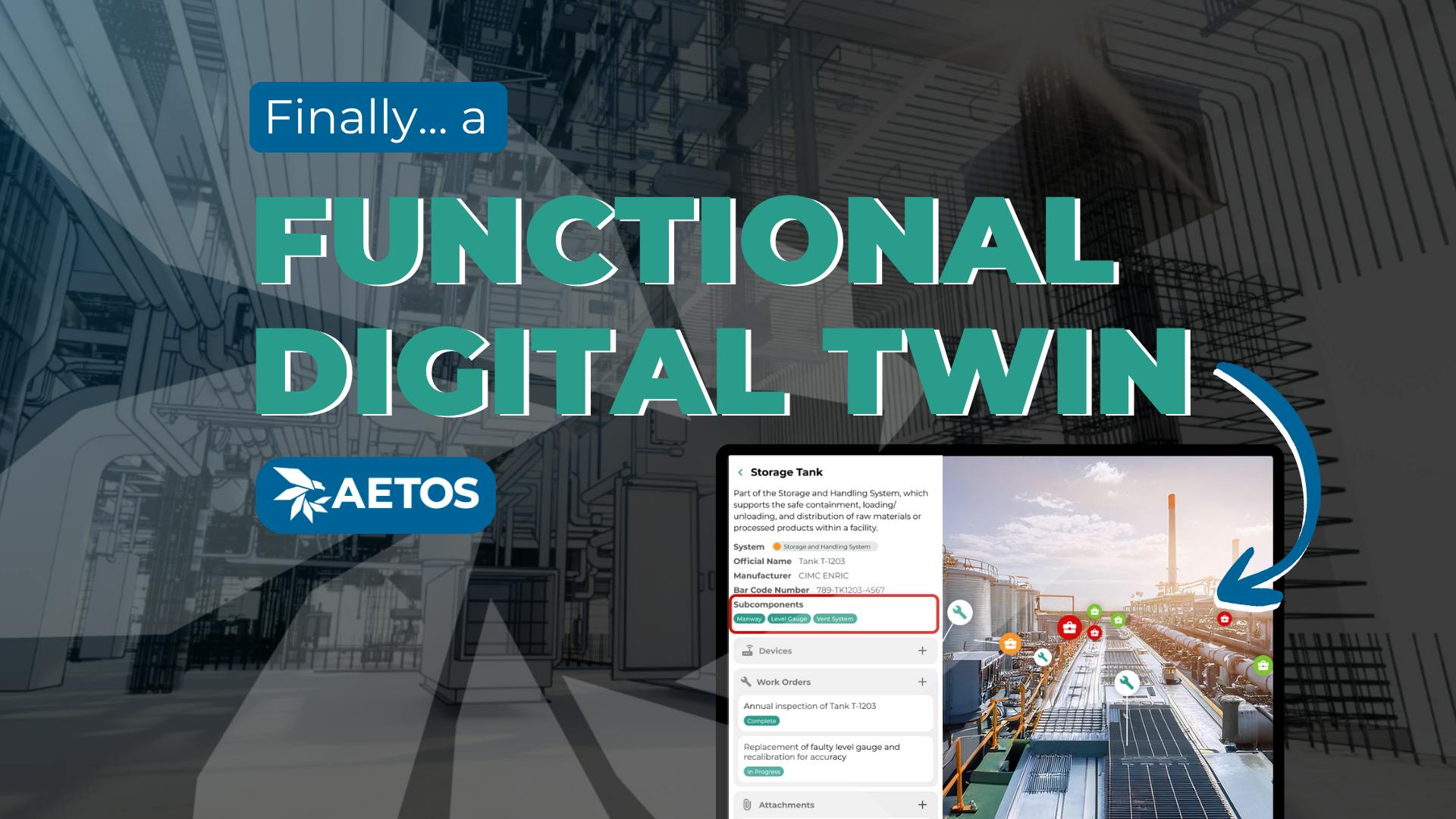

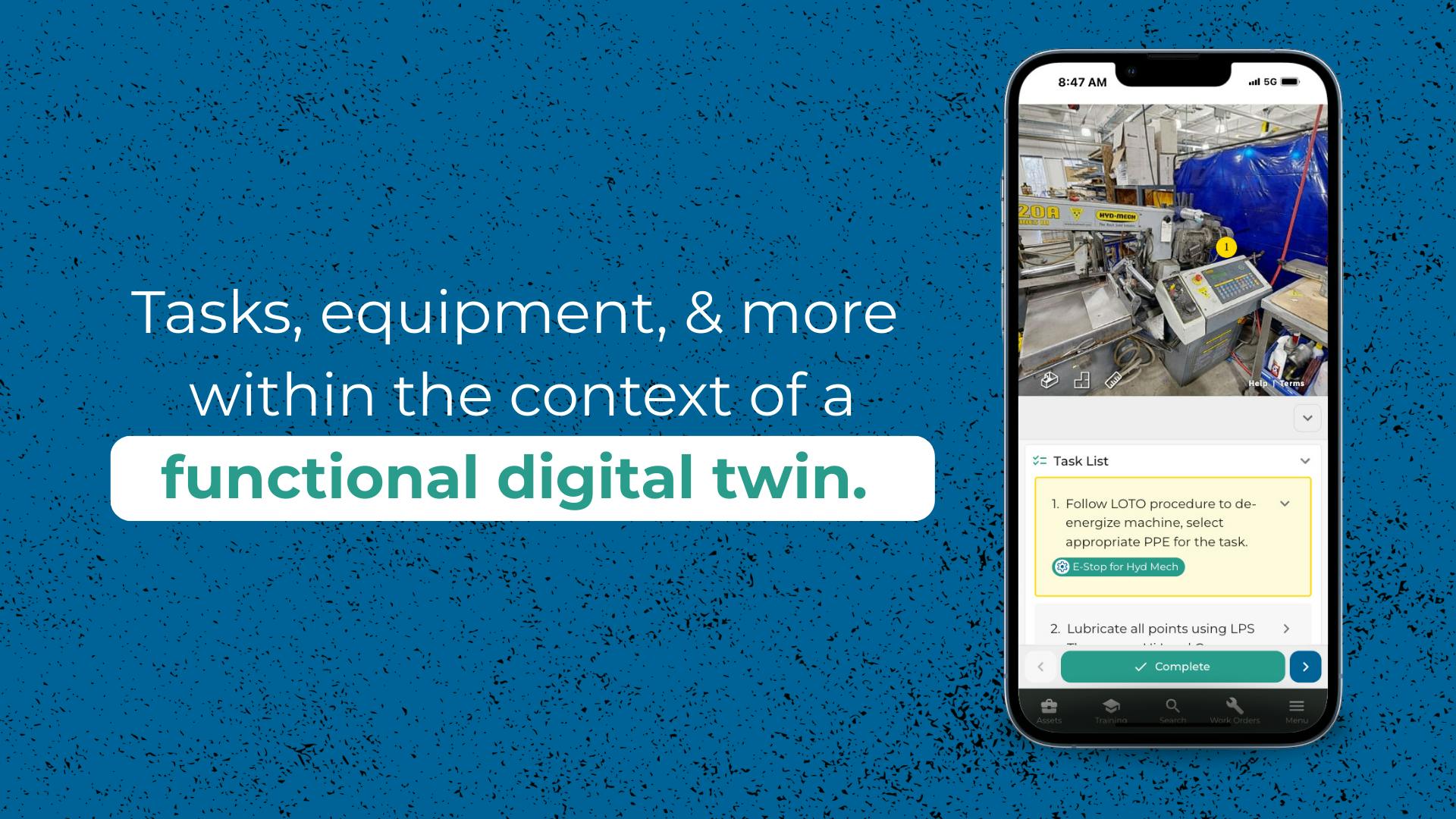

Aetos is the most visual solution for the Connected Worker. Seeing tasks, equipment, and more within the context of a functional digital twin is changing how organizations are able to manage, maintain, and train across their facilities.

What is a Connected Worker?

There’s a limited perception that “connected worker” is simply a technician holding a mobile device.

Although that’s a good place to start, a connected worker is someone empowered with the right information, at the right time, in the right context. They’re digitally linked to their environment, their team, and their tools.

Instead of operating in silos or relying on outdated binders, connected workers move confidently through complex facilities with knowledge at their fingertips and the ability to collaborate in real time.

Organizations are seeing that by connecting their workforce to the tools and information they need (on a single pane of glass, mind you) means bridging the gap between people, processes, and technology.

It’s allowing frontline workers to access digital procedures, training, and asset information as well as creating alignment across every layer of the organization. In practice, this turns daily tasks into opportunities for continuous improvement, where, theoretically, every worker on every shift can contribute insights and best practices.

At its core, the connected worker is not about replacing people with technology, but rather about empowering people with technology. When workers are supported with clarity, visibility, and collaboration, they’re safer, more confident, and ultimately more effective in their roles.

How Aetos is Connecting Southern Company Workers

At a time when technological advancements are reshaping entire industries, Southern Company continues its longstanding tradition of embracing solutions that enhance operational efficiency, safety, and reliability.

One example of this commitment is the recent testing and ongoing implementation of Aetos technology at Alabama Power’s Plant Barry and within Power Delivery, with near-term plans to expand to other generation and delivery sites across the Southern Company system.

By using Aetos’ platform, Southern Company is giving its workforce a powerful connected worker experience. Engineering, operations, and maintenance teams can now access a high-resolution digital model of their facilities, providing a level of detail that allows for virtual walkthroughs and inspections without the need for constant physical presence.

Workers can also assess equipment documentation remotely, review training materials, identify potential issues, and plan maintenance activities with precision.

The benefits extend beyond efficiency. Safety is enhanced by reducing unnecessary on-site inspections. Planning and collaboration are streamlined, with engineers, planners, and field technicians all accessing the same detailed models for a unified approach to decision-making.

Additionally, substations and plant infrastructure are comprehensively mapped, enabling better outage response, inspection planning, and upgrade management.

This initiative is part of Southern Company’s broader Connected Worker program – an intentional strategy to ensure field workers have access to asset information, engineering documents, maintenance records, and site-specific training.

By equipping teams with this visual and data-rich environment, Southern Company is simultaneously improving operations and future-proofing its workforce against the challenges of knowledge transfer and industry demands.

Why Even More Organizations Are Adopting This Approach

It’s not too hard to imagine why organizations want their workforce to be safer, more confident, and more effective in their tasks. The idea of the connected worker has taken shape and taken flight out of necessity to limit lag and the desire to have more productive operations.

The timing of this shift is intriguing as well.

Many industries are facing a perfect storm: aging infrastructure, an experienced workforce heading into retirement, and younger generations less likely to stay in one role for decades. Add to that the increasing demands of compliance, efficiency, and safety, and it’s clear why organizations are rethinking how they equip their teams.

Being connected is now more about resilience than convenience.

Organizations also recognize that the pace of change is accelerating. Regulatory requirements, sustainability targets, AI at every corner, and new energy systems are reshaping how work gets done. Companies that can adapt quickly by keeping their workforce connected and informed gain an edge in meeting these new demands.

Adoption is not just being driven by leadership but also by the workforce itself. Workers increasingly expect modern tools on the job – which isn’t an unjustified expectation as society uses apps, data, and real-time communication in their personal lives.

Even though there are tangible benefits to connecting a worker to the information they need, meeting these expectations helps organizations attract and retain top talent in industries where skilled labor is scarce.

The risks of staying disconnected are clear: Outdated SOPs, siloed systems, and tribal knowledge lead to rework, downtime, and costly mistakes.

Over time, organizations that fail to connect their workforce will face widening performance gaps compared to competitors who embrace this transformation.

Proof in the Numbers

Industry leaders like Southern Company are reporting measurable results when connecting their workforce with Aetos:

- 10%+ lower operational costs tied to rework, overtime, and inefficiency

- 20% shorter project timelines through better collaboration

- 30% higher retention when institutional knowledge is captured and shared

- 40% quicker resolution of issues with visual SOPs and remote access

- 50% faster onboarding of new technicians

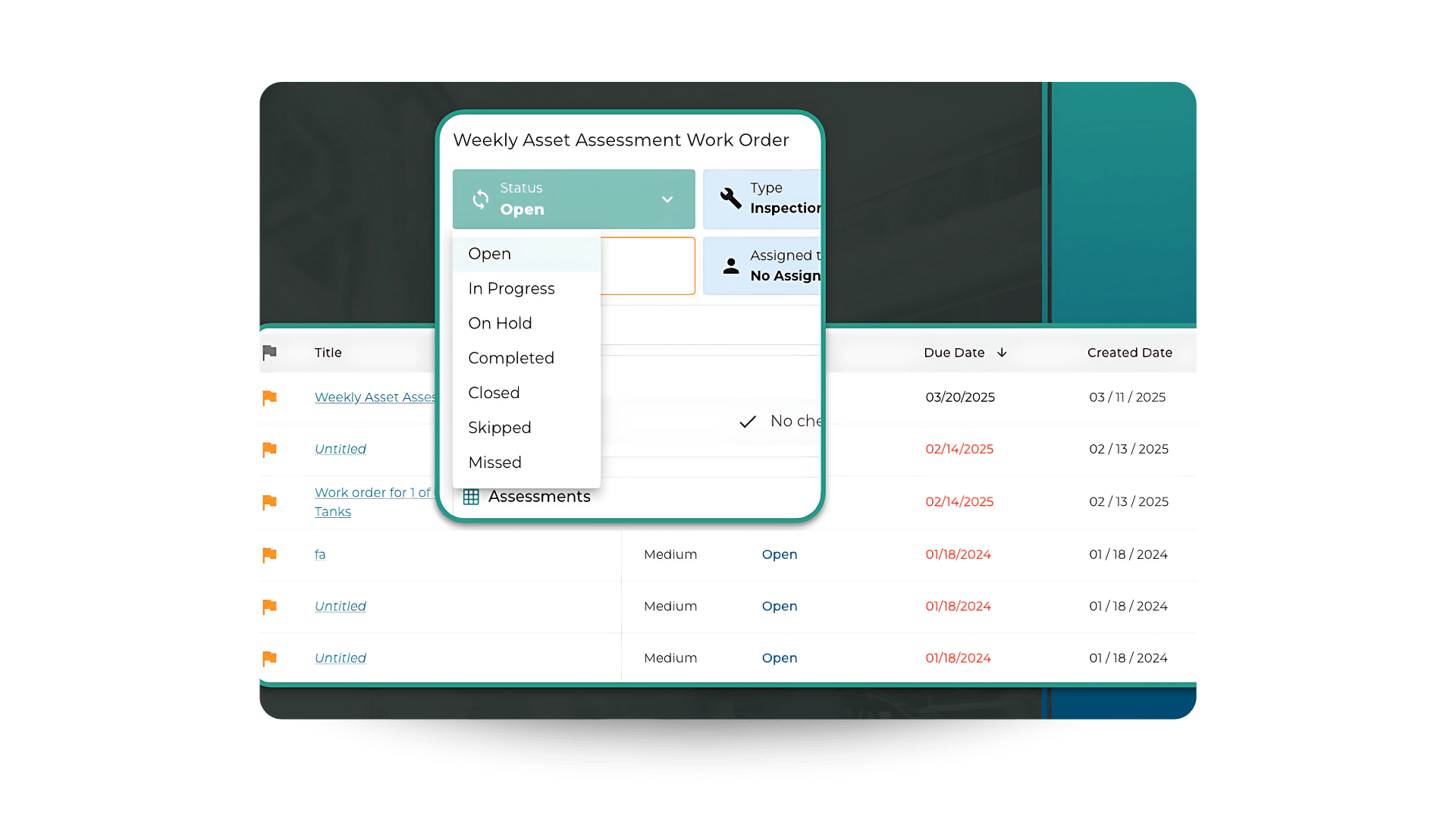

- A significantly better user experience in managing Work Orders

- Reduction in compliance issues and safety reports

- and more

These numbers illustrate a shift from theory to reality.

The ROI of the connected worker isn’t abstract. It’s backed by tangible improvements that organizations are measuring across their operations. For many, the payback period on investments in connected worker technologies can sometimes even be measured in months, not years.

What’s also notable is how these outcomes build on each other.

A quick, logical example: Better onboarding means faster retention and fewer mistakes. Fewer mistakes reduce downtime. Less downtime improves project speed and lowers overtime costs. The result is a compounding effect that reshapes performance at every level of the organization.

When you add workforce retention to the mix, there’s increased value. Retaining skilled employees reduces training costs, preserves institutional knowledge, and helps build a culture of continuous improvement. These benefits reinforce one another, making the connected worker strategy a cornerstone of long-term competitiveness.

The Role of Visual Technology in Enabling the Connected Worker

What makes the connected worker possible today is the convergence of immersive visualization, data integration, and intuitive digital tools. With advancements in 3D imaging and digital twins, entire facilities can now be mapped and navigated visually.

Aetos has been described as a “Google Street View” for operations. Layering asset data, SOPs, and live inputs into this digital environment allows workers to orient themselves, access information instantly, and execute with clarity – all from the plant floor, conference room, or across the State.

Context-rich enablement is what elevates the idea of “connected” from concept to practice.

Visual technology is particularly powerful because it speaks the universal language of context. A floor plan or spreadsheet may require interpretation, but a visual walkthrough shows a worker exactly where they need to go and what they need to do. Such visibility inherently eliminates ambiguity, speeds up execution, and makes training more intuitive.

Equally important is how these tools unify data streams. Maintenance records, compliance documentation, IoT sensors, and live operations data can all be aggregated into one digital environment. Instead of toggling between systems, finding the right flash drive, or chasing down paper files (in the filing cabinet down the road), workers gain a single source of truth that supports consistent decision-making.

Final Thoughts

The connected worker initiative that so many organizations are seeking to solve is more than a buzzword.

It’s a fundamental shift in how work gets done in complex industries.

It’s about the technician – the boots-on-the-ground worker – and giving them the tools, context, and confidence to do their jobs better and safer.

For leaders, the challenge is no longer proving whether the connected worker approach works, but instead, deciding how quickly they can implement it. Those who delay risk being left behind.

The connected worker represents the future of industrial work: safer, faster, smarter, clearer, and more resilient. How is your team seeing the benefits of a connected worker? And if you haven’t already, when will your organization take the step to connect?