6 Reasons Why Top Facilities Managers Leverage 3D Scans for Their Internal Training

Operations managers worldwide are constantly looking for ways to streamline their systems and promote better efficiency within their assets. One of the newer methods many OMs have implemented is immersive 3D scans for internal training.

A 3D representation is built using laser imaging (LiDAR) or photogrammetry to capture a physical environment. The scan is then leveraged as an immersive model that can be accessible and utilized with select software.

This technology is advantageous for the workers within the walls when intentionally put to use. Visualized management platforms can be beneficial for engaging workers in safety-critical positions, such as security officers, maintenance staff, or emergency responders.

But why are top management teams deciding to take the next step in tech for training their employees? We’ve narrowed down the top 6 reasons:

1. Realistic Representation:

Immersive 3D scans can create a detailed and accurate representation of a facility, allowing technicians to familiarize themselves with the physical layout and structure of their space. It’s not a stretch of the imagination to understand the value of operating within a familiar environment – whether the exposure is physical or virtual. Engineers who work in a facility day in and day out benefit, as well as any third-party vendors who might need to view, examine, or interact with relevant context.

2. Secure Simulations:

Virtual scans can provide teams with a visualized understanding of critical spaces without compromising the health of their employees. This engaging experience can be invaluable for staff who may be required to work in complex or dangerous environments. Limiting exposure to hazardous encounters for the sake of training keeps technicians safe, while retaining clarity of their service settings.

3. Improved Safety:

By instructing personnel in an interactive environment, facilities can reduce the risk of accidents and improve safety. For example, workers can practice emergency evacuation procedures without the risk of harm. Additionally, visual guidance that promotes best practices improves overall safety within the workplace; informational scans can also help to identify and mitigate potential safety hazards, reducing the risk of accidents and injuries.

4. Increased Understanding:

Being on the same page is powerful. Visualizing the facility and its various systems is embedded in the function of a 3D scan. Engineers and service technicians can better understand how their machinery or equipment function. Cross-referencing and synergy across a network can allow facility personnel and senior management to work together and optimize performance. And an interactive platform permits all employees to gain a deeper understanding of its layout, features, and functionality.

5. Reduced Costs:

Facilities can trim overhead associated with in-person instruction while still delivering specialized training. Obvious operational costs like travel expenses, re-training, and lost productivity can be mitigated; organizations can even save money during the hiring process, as onboarding times are shortened and retention rates are slowed. Reducing the need for constant in-person sessions can result in significant cost savings for facilities – especially for large or complex industries.

6. Customizable Site-Specific Training:

The majority of top asset managers consider custom training to be the most potent feature of a 3D scan. Digitized virtual environments can be modified to meet the specific guidance needs of different departments, making learning more relevant and effective. Organizations can create visualized simulations tailored to the specific needs of their equipment and workers. This – along with capturing and retaining institutional knowledge – allows personnel to become familiar with operating equipment and its systems, leading to faster and more efficient work. Furthermore, some organizations can offer a platform that can deliver more targeted and effective training courses and curriculum; virtually, facilities can utilize the ability to make instructional changes within critical spaces, giving technicians the most up-to-date intel and methods.

These virtual settings can then be used to create interactive and detailed informational databases, simulations, and models of the asset, allowing engineers and technicians to become familiar with the space and its various components.

Why Aetos?

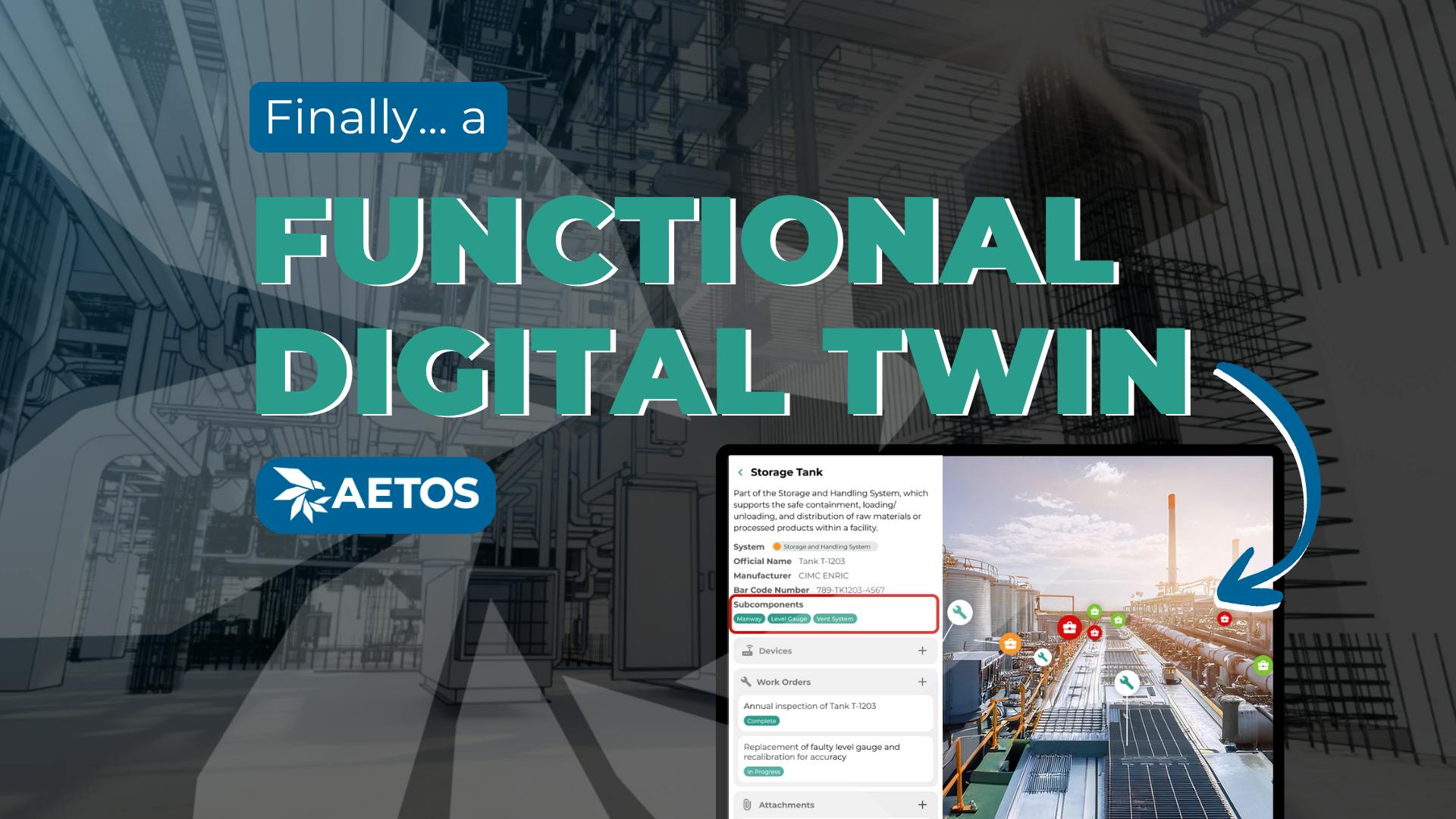

Aetos is intent on delivering visibility and efficiency to facilities personnel. Our immersive 3D platform is becoming an increasingly popular tool for facilities managers as they look to optimize their internal training and operational processes. These visual advantages help our partners reduce costs, increase efficiency, capture critical methods, realize operational data, and improve overall performance.

Now, organizations can provide customizable learning experiences that give workers familiarity with an asset and its systems. With the Aetos platform, environments can further promote best practices and ensure that all staff are on the same page; our partners also can update their dashboard whenever needed or utilize remote collaboration calls within their asset scans, conveniently providing service technicians with the most relevant guidance.

As facilities become more complex and the need for efficient and effective training grows, it is likely that 3D scans will become an even more valuable tool for asset and facilities managers in the future.

Reach out to our team today to request a demo and see our platform at work!