6 Ways One Tool Makes Sustainability More Attainable

Sustainability and measures to fight climate change are hot topics in the built environment.

As we continue to witness the impacts of greenhouse effects and the need for responsibility involving natural resources, it’s clear that new ways to design and operate more sustainable buildings are judiciously necessary.

A critical, up-and-coming tool that is being used for better environmental stewardship is 3D scanning. This technology is quickly gaining popularity and can function as a companion for sustainability initiatives in the built environment – from simple waste reduction strategies to comprehensive energy audits.

What is 3D Scanning?

3D scanning is a process of capturing the shape and appearance of physical objects or spaces and then digitizing them in a virtual space. Utilizing laser scanning and/or photogrammetry technology, 3D cameras document the geometry, geolocation, and texture of an item or area. This data is then leveraged to create a 3D model which can be used for a range of applications only limited by human imagination.

So How Can 3D Scanning Be Used for Sustainability in Facilities Management?

Specifically for building and facilities operations, there are a variety of ways that 3D scanning can improve sustainability.

1. Building Lifecycle Stewardship

We can better our environment by augmenting lifecycle stewardship. 3D models of a facility can allow FMs to better understand the building’s layout and systems, which can help their teams optimize maintenance schedules and minimize waste. Areas that are prone to wear and tear can be better visualized and addressed, while more efficient routes for cleaning and maintenance crews can be curated for optimized performance. Reducing waste and lowering operating costs leads to better building lifecycle management.

2. Retrofits and Renovations

This technology can be invaluable in assisting with retrofits and renovations. By creating a 3D model of an existing building, architects and engineers can design new systems and features that will diminish the building’s environmental impact. Executing more efficient systems or optimizing facility features – like taking advantage of natural light and ventilation with improved window placement – can lead to better sustainability metrics.

3. Equipment Management

3D scans can be used to design and optimize the management of new and existing equipment at a facility in a few different ways. Replacing a component can be clearer and quicker with visual referencing. Changing out larger machinery is easier with a virtual space to ideate and plan in. And when adding new equipment – like solar panels, ventilation systems, or other sustainability mechanisms – architects and engineers can determine the optimal location and orientation for maximizing energy objectives. This technology can easily lead to a reduction of a facility’s reliance on traditional energy sources, resulting in lower energy bills and a mitigated carbon footprint.

4. Remote Collaboration

Hundreds of transit hours – sometimes thousands – could be saved each year by organizations that intentionally leverage advanced 3D scanning technology. Visual copies of internal spaces and equipment can lead to heightened clarity for on-site technicians, off-site managers, and even third-party vendors. Within a digital space, teams can virtually walk and discuss an area, solving problems in a digital environment. 3D scans unlock the ability to drastically cut unnecessary gas emissions associated with air and ground transportation.

5. Disaster Response

When dealing with a major disaster, the most powerful responses have the most clarity and confidence. What follows after a hurricane or earthquake can look very different, depending on the level of preparation and information an organization employs. 3D scans are advantageous for pre-disaster data, emergency response routes and procedures, and even post-disaster decision-making: a comprehensive capture can allow engineers to observe and identify areas that are unsafe and in need of repair or reinforcement, improving overall safety and minimizing the risk of further damage or collapse.

6. Energy Efficiency Audits

Finally, 3D scanning can improve sustainability in building operations by performing better energy efficiency audits. Engineers and architects can analyze the building’s energy usage and identify areas for improvement by gathering representational data about systems and components. Lighting, HVAC, and insulation are just a few ways that 3D visualization technology can provide clarity and data for owners and managers, making energy efficient audits more accessible and expeditious. (IoT data can also be linked to 3D scans, permitting live readings for critical spaces – leading to even more clarity and better energy efficiency.)

Use 3D Scanning Today

Visualizing facility logistics and initiatives with 3D scans leads to enhanced sustainability in the built environment. By documenting and recording valuable spaces and their components with this technology, architects, engineers, facility managers, and other building personnel can identify areas for improvement and optimize systems for energy efficiency.

A real-world impact and benefits of utilizing 3D scanning on building operations exist. And as we pursue improving our environment and charge toward sustainability goals, there is a prudent obligation to leverage every resource available for our buildings, ecosystems, planet, and future.

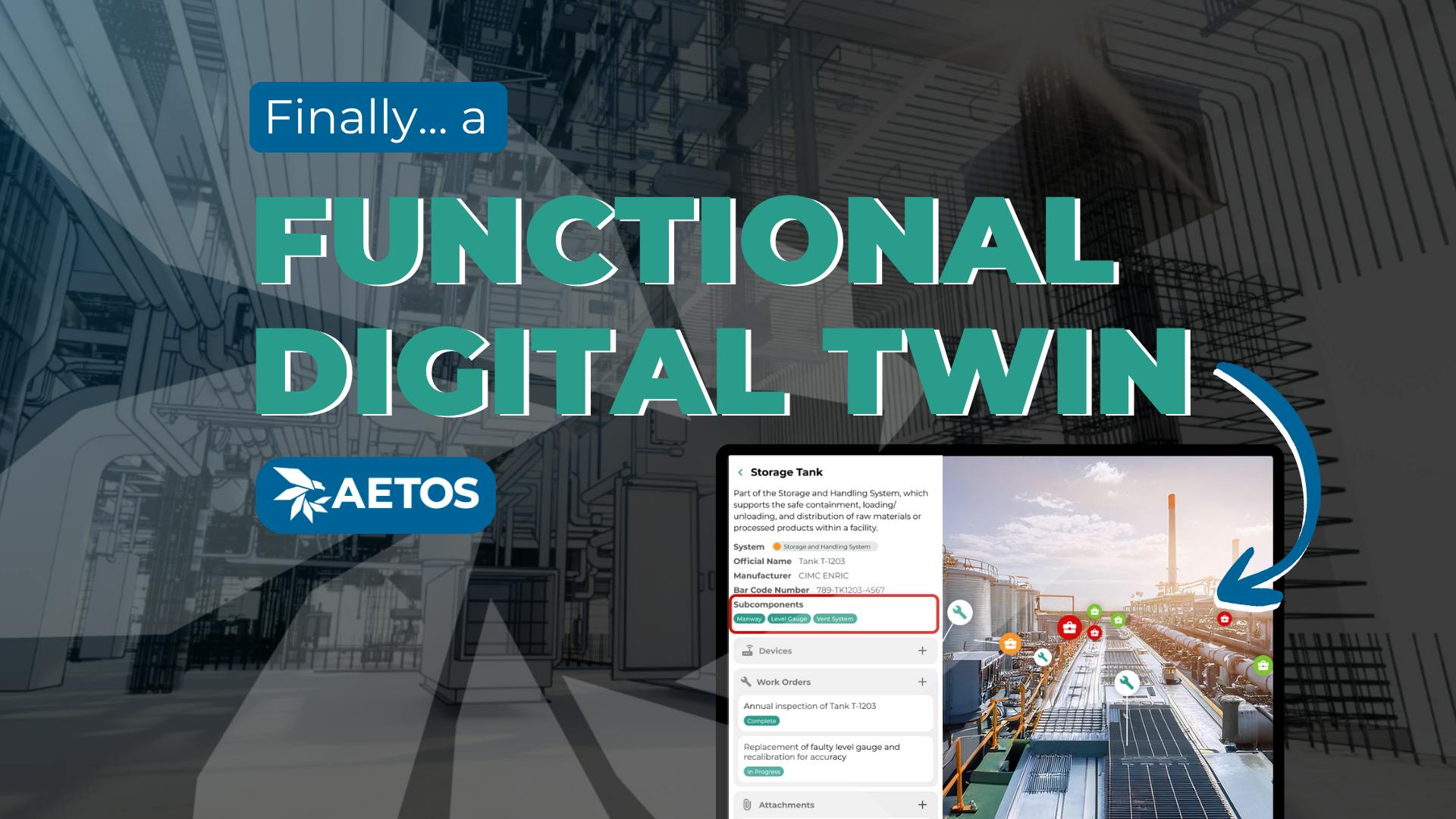

If you or your organization is interested in taking the next steps in environmental stewardship and want to see how 3D scanning can benefit your facilities, reach out to Aetos today. Empower your technicians. Visualize your operations. Facilitate sustainability.