Asset Management Innovation: Leveraging the Power of 3D Visualization

Vision and action are tightly bound together. In the built environment, sight is the most critical sense for technicians, engineers, and building personnel, who must see their surroundings and observe their equipment before they act.

Operations and Facilities Managers (FMs) fulfill a multifaceted and demanding role, requiring them to juggle various tasks. Maintenance planning, equipment optimization, resource allocation, and safety protocols are just a few of the responsibilities they oversee.

The key to their success in these roles is having a comprehensive understanding of all assets under their supervision. Top managers use data to make informed decisions, so traditional management methods involve color-coded spreadsheets and shelves of binders: a comprehensive way to hold meaningful information. (Some facilities don’t have any information written down and instead rely on one building professional’s brain alone – a precarious place to be as an organization.)

But what if those spreadsheets could tell more of the story? What if those binders could give greater clarity without the scavenger hunt? What if facilities teams could see more than simply cataloged data points?

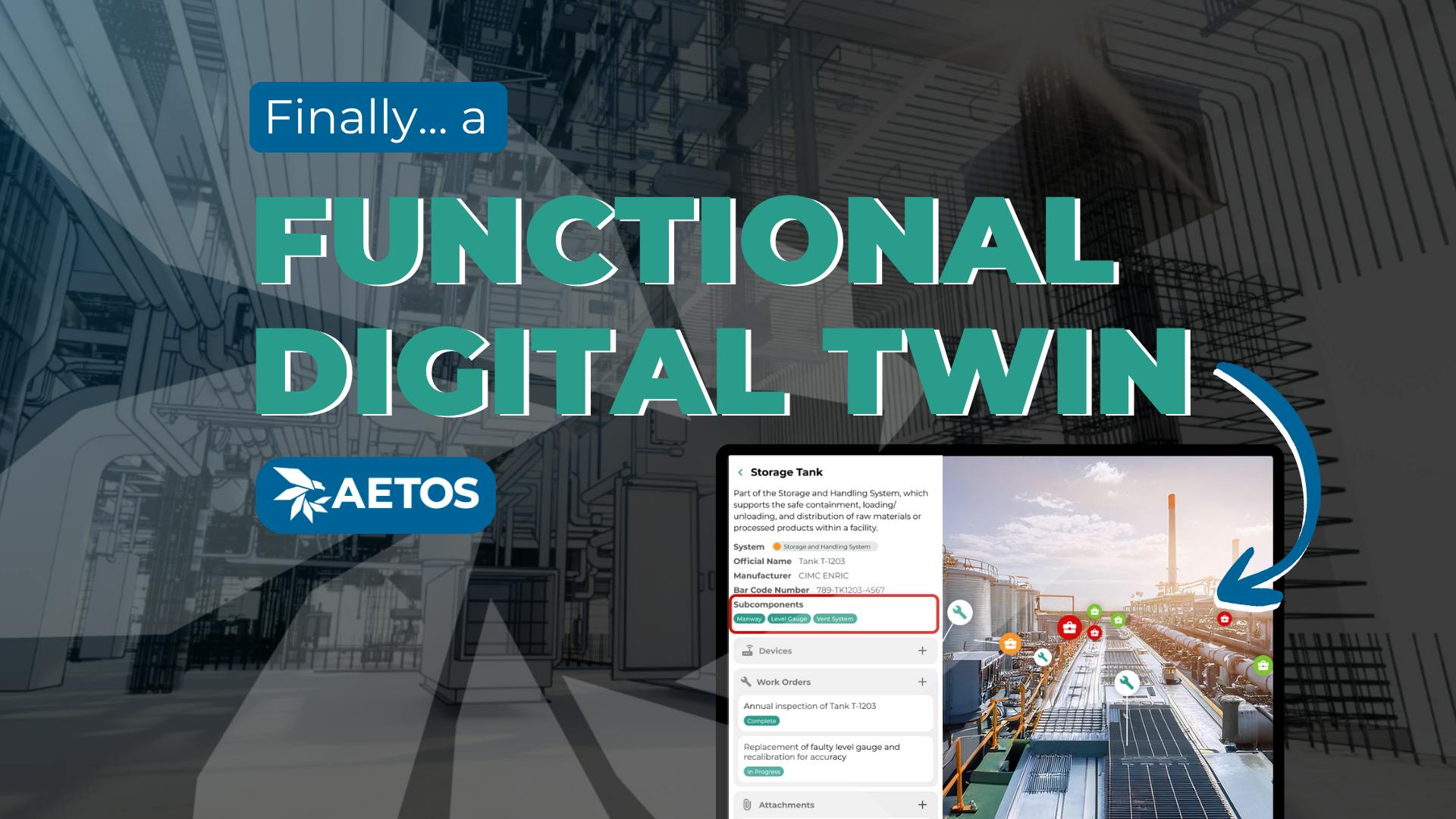

That's where Aetos Imaging's Visual Asset Management feature comes in, acting as a game-changer in the field of operations and facilities maintenance.

Better Clarity, Better Management

First, let's really set the stage by discussing the traditional approach to asset supervision.

Conventionally, managers use spreadsheets or dedicated software to track assets and their schedules. This approach provides crucial data such as location, status, maintenance records, and more. Teams also use binders and clipboard-and-pencil systems, along with the method where “one guy knows all”.

However outdated or inefficient these practices are, they’re also disconnected from the real-world, physical context of the equipment (and the facility itself). These approaches are less intuitive and require greater training time investments in order for FMs to connect their data with real physical assets.

Aetos' Visual Asset Management feature revolutionizes this approach by integrating a 3D virtual model of the facility with a comprehensive asset database (and more) for clearer visibility. This means that every piece of equipment, component, or infrastructure element is not just a row in a spreadsheet but a visually identifiable object within a digital replica of the facility.

Practically speaking, this visual context greatly simplifies both understanding the building and operating it efficiently. By clicking on a specific asset in the 3D model, an FM can immediately access all its relevant information. This could include details like specifications, warranty information, historical maintenance records, upcoming maintenance schedules, and more. (Like, “integrating-IoT-live-network-component-readings” more.)

It’s clear that having this information immediately accessible in a visual context saves time and eliminates the need for tedious cross-referencing (and the mistakes that can happen in the process).

More Visibility, More Efficiency

When a physical problem arises in the built environment, there may be multiple ways to get to a solution. And sometimes the simplest solution isn’t the easiest, or even the most efficient. The color-coded spreadsheet data and the shelves of binders can become the proverbial haystack preventing a technician from solving the problem.

The Visual Asset Management feature from Aetos enables more effective planning for routine maintenance and rapid response to equipment breakdowns. A detailed digital twin of the facility allows FMs to identify the exact location of an asset needing attention, as well as tying explicit documentation and processes to the equipment at hand. Aetos lets organizations plan the most efficient service steps for maintenance personnel, whether the organization is using internal technicians or – more critically – third-party service providers.

Further Use, Further Impact

Lastly, Aetos' Visual Asset Management feature is not static. It's an interactive tool that can reflect equipment history, service notations, and a facility’s work order schedule – historical, live, or upcoming. A typical blueprint or CAD can’t simultaneously deliver site-specific visual renderings, as well as preventative maintenance procedures and history.

Organizations accurately display their equipment and spaces within a photorealistic setting on the Aetos platform. As changes occur in the physical facility, the virtual model can be updated to reflect these changes, promoting clarity and confidence for team members.

Without delving too deeply into the full array of features within Aetos, it’s worth noting that FMs can also use their visualized environment to do things like: augment site-specific training, cross-reference equipment across an entire portfolio of facilities, and even collaborate directly with vendors and team members within their digital scan.

Visualize Your Operations

In essence, the Visual Asset Management feature offered by Aetos brings an unprecedented level of visibility and control to Operations and Facilities Directors. It combines the detail of traditional asset management software with the intuitive understanding offered by a 3D representation of the actual facility. It’s more than just an innovative tool: it's a transformative approach to operations that is poised to redefine the industry standards.

Reach out to us today to learn more about how Aetos can help you visualize your operations.