How 3D Scans Can Assist Service Providers

In today's fast-paced world, outsourcing maintenance tasks to third-party service providers is a common practice. However, this process can sometimes be time-consuming and costly, leading to inefficiencies and resource wastage.

3D scans can revolutionize the outsourcing of maintenance tasks (i.e. mechanical, electrical, plumbing, jobs) by saving establishments valuable time, money, energy, and other resources.

Q: What are 3D scans, and how do they work?

A: 3D scans involve capturing and displaying detailed digital representations of physical objects or spaces using specialized equipment. High-resolution cameras that use laser and/or photogrammetry imaging technology enables a physical space to be virtualized and visualized in a digital format.

Q: What are some ways that 3D scans could assist institutions when contracting out maintenance or repair tasks?

A: 3D scans offer several advantages that can significantly enhance the outsourcing process:

- Clearer Communication: 3D scans grant detailed visual information to technicians, ensuring clear and precise communication. Instead of relying solely on verbal descriptions or 2D drawings, service professionals can access the virtual replica, both before and during their task.

- Improved Planning and Preparation: By sharing 3D scans with specialists in advance, companies permit contractors to thoroughly analyze the task and develop a well-informed plan. Third-party experts can assess potential challenges, identify necessary equipment, and devise efficient strategies, reducing the time spent on-site and the likelihood of unexpected complications.

- Remote Troubleshooting: In some cases, service providers can offer remote troubleshooting while utilizing 3D scans to diagnose problems, propose solutions, and recommend the required parts or tools. This minimizes the need for physical visits, saving time and expenses associated with unnecessary travel.

- Accurate Quoting and Bidding: Contractors can utilize 3D scans to generate accurate quotes or bids for maintenance tasks by having a digital model to virtually walk and observe. This can accelerate the bidding process as travel is mitigated; a comprehensive understanding of the space, project scope, and potential complexities enables them to visualize more precise estimates, reducing the chances of unexpected cost overruns.

- Efficient Resource Allocation: With 3D scans, operators can better allocate their resources. By analyzing the virtual replica, they can determine the specific tools, equipment, and materials required for the task. This minimizes the risk of carrying unnecessary inventory or making multiple trips to the site, ultimately saving time, money, and other resources.

Q: Are there any additional benefits of using 3D scans for subcontracting tasks?

A: Some other notable benefits include:

- Improved Safety: Service professionals can assess potential safety hazards using 3D scans, allowing them to plan accordingly and take preventive measures. This helps minimize accidents, injuries, and associated costs.

- Historical Documentation: 3D scans serve as valuable historical documentation of the object or space. Companies can maintain an archive of scans for future reference, making it easier to track changes, plan renovations, or address recurring maintenance issues – as well as providing information to the expert.

- Increased Accountability: Digital replicas can create a transparent and accountable environment. Technicians are able to refer back to 3D scans to demonstrate the scope of work completed, facilitating accurate invoicing and resolving any disputes regarding task fulfillment.

Q: We’ve talked mostly about how 3D scans help organizations. But how can 3D scans assist service providers?

A: When a professional is subcontracted to inspect and repair a facility, the most significant variable for a project is always time. Whether that’s time finding the right facility, locating the correct piece of equipment, or traveling back and forth for additional tools or inventory, an unpredicted amount of time is expended for each work order.

On some jobs, technicians spend up to 40% of the project hours looking for the right machinery at the right location. 3D scans can alter the variable of time and expedite the entire process.

A quick virtual tour can be offered to third-party specialists. Contractors can also be granted access to the 3D scan while completing their task if there’s pertinent historical information or component specifics; this offers significant visual support and equipment wayfinding to contracted technicians. Now, service providers are given unprecedented clarity, leading to quicker close-outs, more confidence, better communication, clearer expectations, faster repairs, and shorter facility or equipment downtime.

Q: How do 3D scans contribute to a more sustainable outsourcing process?

A: By minimizing physical visits and optimizing resource allocation, organizations can reduce carbon emissions associated with transportation and minimize waste generated by unnecessary trips or duplicated efforts. This aligns with the global trend of establishments embracing sustainable practices and reducing their environmental footprint.

Q: Can 3D scans improve the quality of outsourced maintenance tasks?

A: Although it can’t be explicitly claimed, a detailed, visual understanding of the task through 3D scans would lead to improved quality. Clarity is powerful. Leveraging a digitized space can reduce errors, enhance precision, and ensure that maintenance tasks are carried out to the highest standards.

Q: How much time can organizations save by utilizing 3D scans in outsourcing maintenance tasks?

A: According to a 2016 study conducted by McKinsey & Company, establishments using 3D scanning technology in maintenance processes reported a reduction in project duration by 20% on average. This time savings can be attributed to improved planning, enhanced collaboration, and more efficient task execution facilitated by 3D scans.

Q: What is the cost-saving potential of using 3D scans in outsourcing maintenance tasks?

A: An estimated cost savings ranging from 10% to 25% can be achieved by companies that properly utilize 3D scans for third-party work orders. Deloitte found that organizations adopting 3D scanning technology for design, maintenance, and repair has a positive impact on supply chain logistics and metrics. These savings result from reduced travel expenses, optimized resource allocation, accurate quoting, and minimized rework, leading to improved operational efficiency and cost containment.

Q: What other ways can corporations use 3D scanning for?

A: This special technology can be advantageous for multiple uses across multiple industries. 3D scans unlock a new dimension of operation and support, enabling institutions to take on new initiatives, augment current procedures, or better their bottom line:

- The British Museum is looking at leveraging 3D technology to monetize special artifacts: digital scans can be physically printed, allowing customers to hold and interact with ancient replicas.

- Ford Motor Company used 3D scanning to accurately recreate details and reproduce components from their 106-year-old Michigan Central Station.

- Airbus is employing drones and other 3D equipment to conduct inspections and giving operators more data for their decisions.

Q: What if my facility doesn't have 3D scans yet?

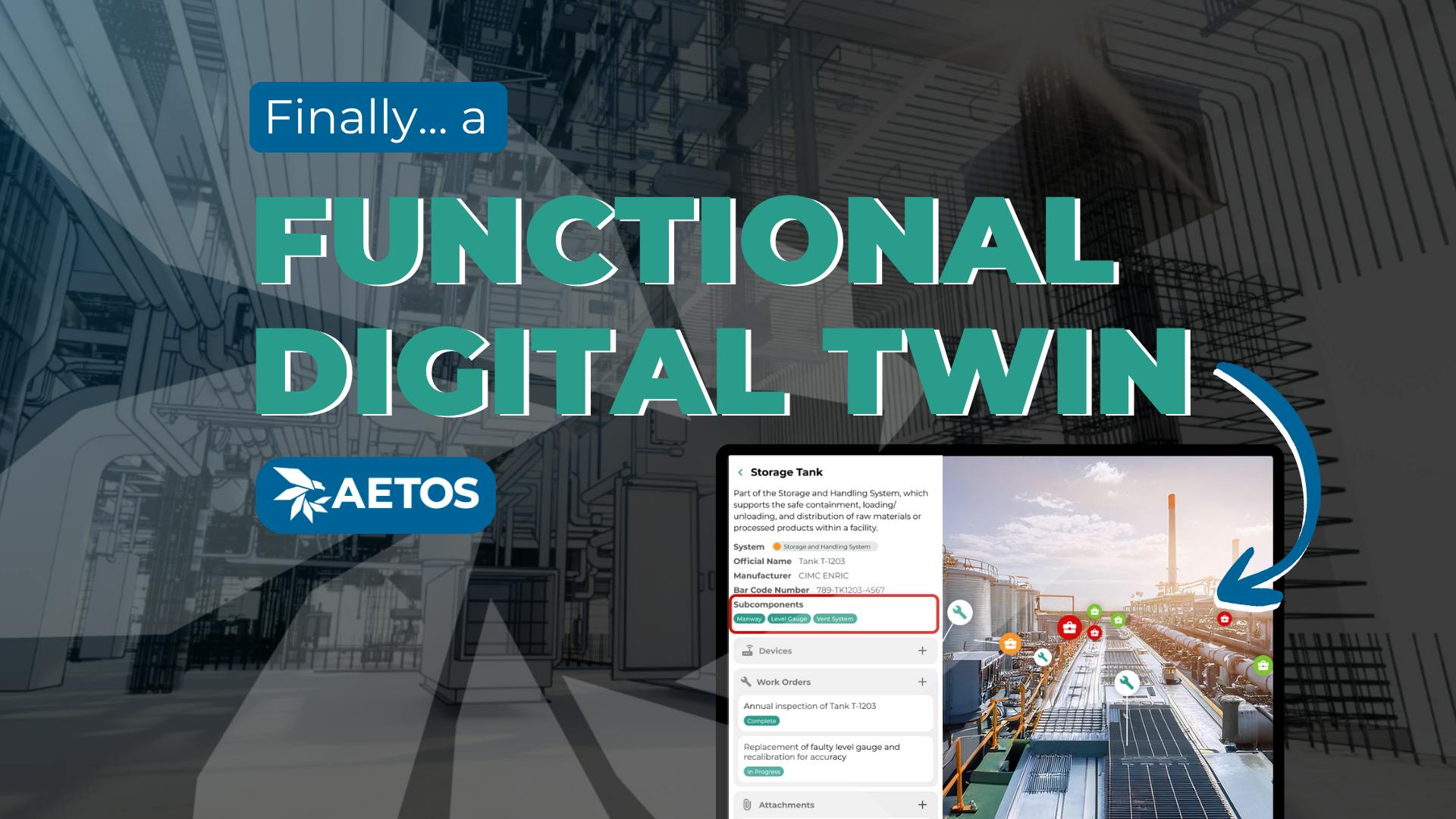

A: Reach out to Aetos! We are the premier provider for organizations looking to streamline their operations and leverage technology to fit their management needs. With Aetos, partners can unlock advanced site-specific training, user-friendly equipment databases, high-visibility remote collaboration and more.

Q: How does Aetos capture and display 3D scans?

A: Aetos captures facilities with top-of-the-line, 360° cameras. Our professional-grade cameras use lidar technology to record and visualize accurate 3D models that can be viewed, measured, and analyzed on any smart device. We scan your designated spaces and digitize it in the cloud; Aetos creates a virtual replica that you can use to explore, train, document, and collaborate collectively on our platform.

Visualize Your Space. Upgrade Your Operations.

By capitalizing on 3D scans in the outsourcing of maintenance tasks, organizations can experience significant savings in time, money, and other initiatives. The detailed visual information supplied by 3D scans enhances communication, streamlines planning, enables remote troubleshooting, facilitates accurate quoting, optimizes resource allocation, and promotes safety and accountability.

This innovative technology is a game-changer in the service provider landscape, revolutionizing the way companies collaborate with third-party professionals. Reach out to Aetos today and see how your facilities could benefit by bringing 3-Dimensional clarity to your operations.