5 Things We Learned in 2025

February 02, 2026

Continue reading ➔

A Safer Tool for Operations: 3D Scans for Technical Tasks

November 04, 2025

Continue reading ➔

The Missing Layer of O&M Systems: Visual Scans

October 07, 2025

Continue reading ➔

The Connected Worker for the Present and Future: Why Southern Company is Using Aetos

September 04, 2025

Continue reading ➔

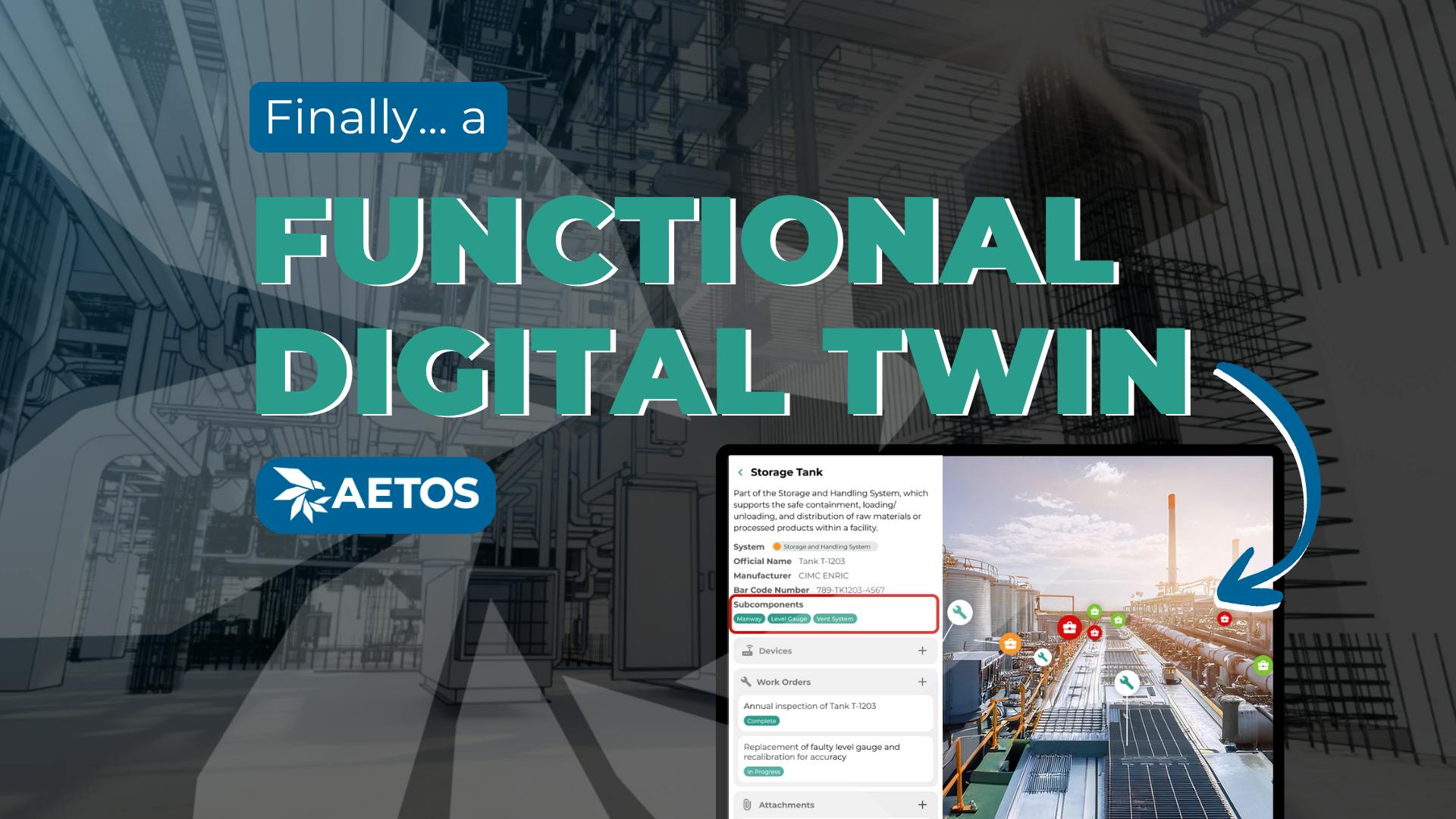

Finally, a Functional Digital Twin.

August 04, 2025

Continue reading ➔

Why Your Facility Needs Its Own “Google Street View” for Operations

July 01, 2025

Continue reading ➔

Manufacturing Training: Revolutionary 3D Visual Courses

January 28, 2025

Continue reading ➔

Work Orders Have Never Looked Like This Before

December 06, 2024

Continue reading ➔

These Phrases Are Symptoms of Ineffective Process Management

October 17, 2024

Continue reading ➔

15 Asset Management Best Practices for Better Efficiency and Reliability

September 18, 2024

Continue reading ➔