Illuminate Facility Operations with Efficient Asset Management

August 31, 2024

Continue reading ➔

A Looming Crisis: The Widening Knowledge Gap in Facility Management

August 01, 2024

Continue reading ➔

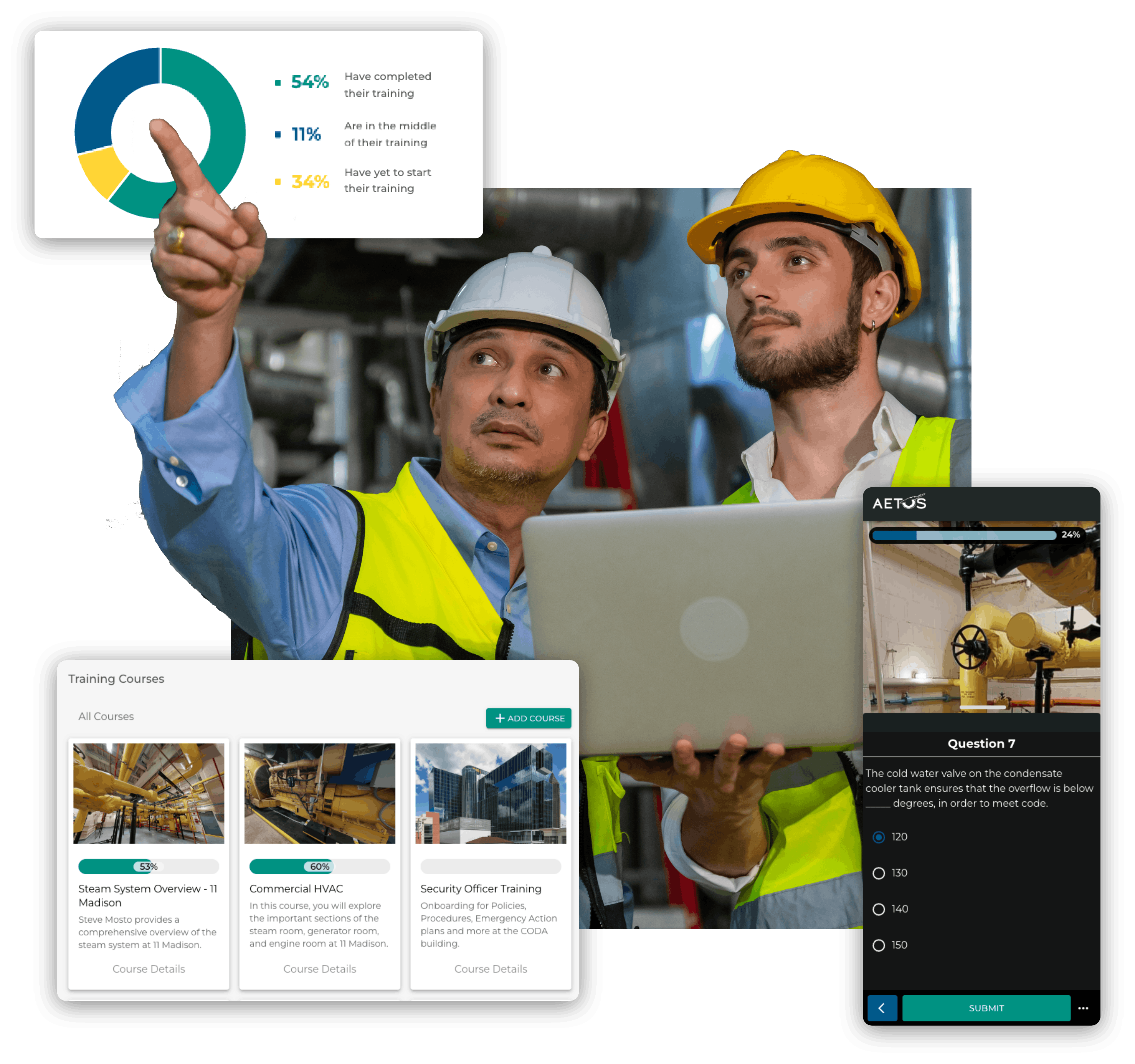

Unparalleled Clarity for Training & Compliance: 7 Reasons to Leverage Your Digital Twin for Employee Training.

July 12, 2024

Continue reading ➔

Enhancing Energy Management & Cost Savings with Aetos Imaging

June 10, 2024

Continue reading ➔

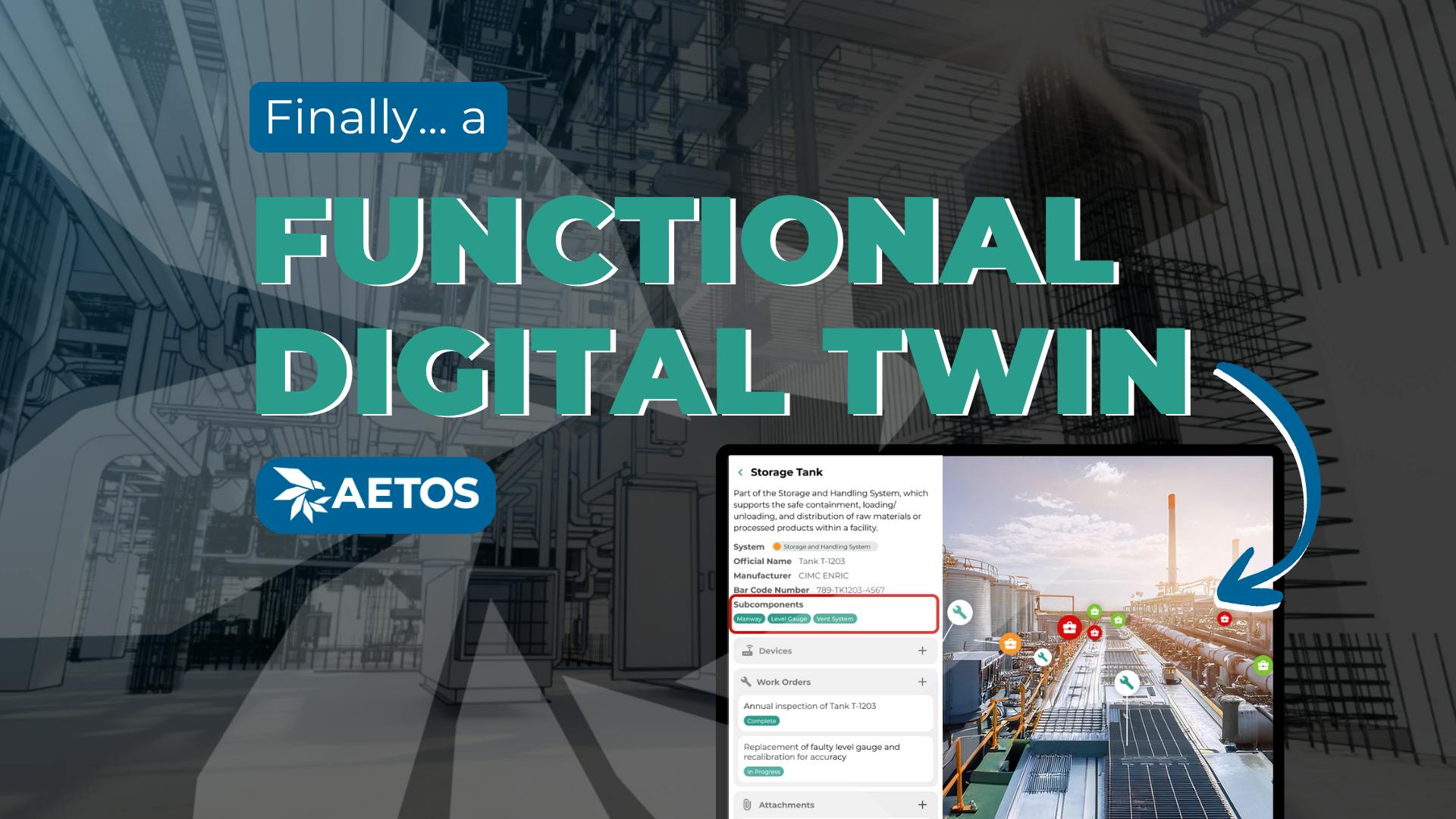

What Is VMMS? And Why Now?

June 04, 2025

Continue reading ➔

Aetos Announced As A 2024 Top 10 Innovative Company In Georgia

March 19, 2024

Continue reading ➔

Beyond the Buzzwords: 5 Terms Defining Next-Generation Utilities [2026 Update]

February 04, 2026

Continue reading ➔

Plausible Emergencies: Navigating Building Stress with Effective Plans

January 10, 2024

Continue reading ➔

What is Continuous Improvement & How Should I Implement It?

November 30, 2023

Continue reading ➔

Efficient Knowledge Preservation: Aetos Operate for Institutional Knowledge

November 01, 2023

Continue reading ➔